Researchers at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) in Golden have created a new type of wind turbine blade made from biomass-based resin that can be chemically recycled, offering a solution to the current practice of disposing of old blades in landfills. The findings were published in the journal Science.

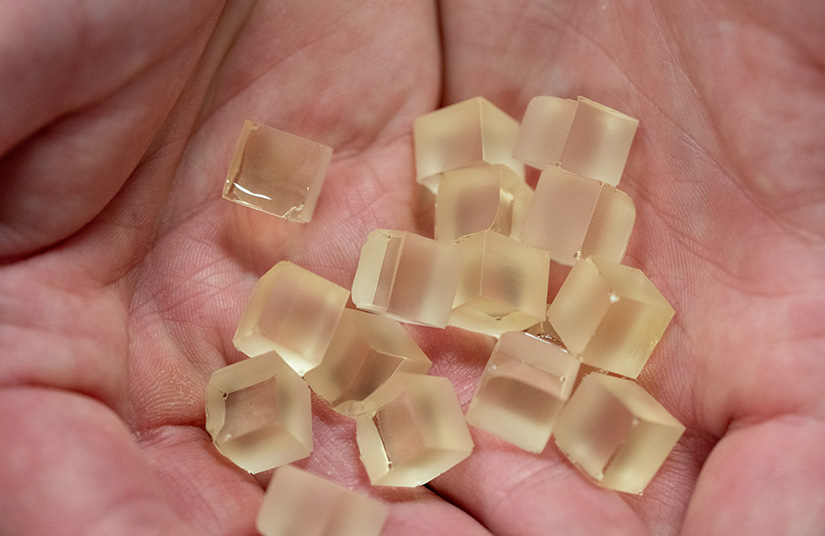

The new resin, made from bio-derivable resources, matches the performance of industry-standard thermoset resin blades and outperforms some recyclable thermoplastic resins. Researchers built a 9-meter prototype blade to demonstrate the manufacturability of the biomass-derived resin, known as PECAN, or PolyEster Covalently Adaptable Network.

The current technology allows wind blades to last about 20 years, after which they are mechanically recycled, often shredded for use as concrete filler. PECAN enables recycling through mild chemical processes, allowing the components to be recaptured and reused. Ryan Clarke, a postdoctoral researcher at NREL and lead author of the paper, said, “It is truly a limitless approach if it’s done right.” He noted that their chemical process could fully break down the prototype blade in six hours.

The research, reported in the paper “Manufacture and testing of biomass-derivable thermosets for wind blade recycling,” included efforts from five NREL research hubs, such as the National Wind Technology Center and the BOTTLE Consortium. The team demonstrated an end-of-life strategy for the PECAN blades and proposed recovery and reuse methods for each component. Johney Green, NREL’s associate laboratory director for Mechanical and Thermal Engineering Sciences, said, “The PECAN method for developing recyclable wind turbine blades is a critically important step in our efforts to foster a circular economy for energy materials.”

NREL is the U.S. Department of Energy’s primary national laboratory for renewable energy and energy efficiency research and development, operated by the Alliance for Sustainable Energy LLC.