Action Engineering, a Lakewood-based firm, has just released a set of Model-Based Definition (MBD) Models and accompanying digital files for public review. While this might sound like technical jargon, this announcement is a significant step toward transforming how things are designed and manufactured—a shift known as the Model-Based Enterprise (MBE).

What Is the Big Deal?

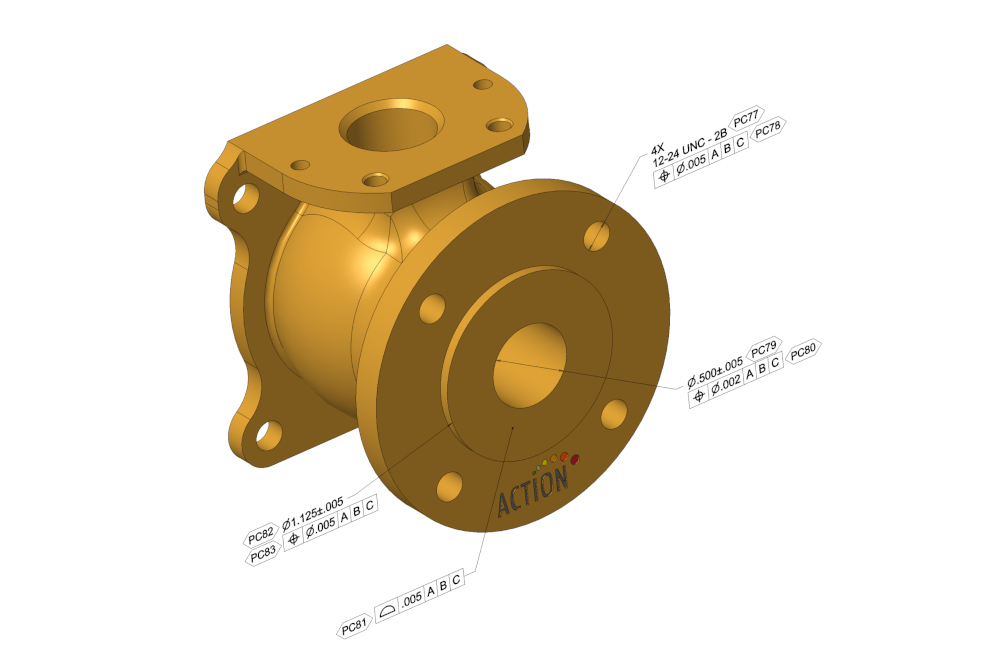

For decades, manufacturing relied on 2D engineering drawings to communicate design intent. MBD changes that by embedding all the necessary information—like dimensions, tolerances, and material specifications—directly into a 3D digital model.

The key importance of Action Engineering’s new release is that these aren’t just any 3D models; they are a **gold-standard reference**. They are meticulously built to comply with the latest, most complex industry standards (like ASME Y14.5 and Y14.41).

- Machine-Readable Data: The models use “semantic,” or machine-readable, annotations. This means software systems—from design to inspection machines—can automatically understand the design requirements, eliminating the need for human interpretation and manual data entry errors.

- A “How-To” Guide: By making these models public and seeking peer review, Action Engineering is creating a common, validated blueprint for companies across the aerospace, automotive, medical, and defense sectors that are struggling to adopt MBD effectively.

How Will This Impact the Industry?

This release is aimed squarely at accelerating the industry’s digital transformation.

| Impact Area | Pre-MBD / Drawings | MBD with Reference Models |

|---|---|---|

| Error Reduction | High risk from human misinterpretation of 2D drawings. | Low risk; systems read the data directly and consistently. |

| Automation | Limited to simple tasks; reliant on manual data transfer. | High potential for automation in manufacturing and quality control. |

| Time to Market | Slowed by drawing creation and quality checks. | Faster integration of design, manufacturing, and inspection. |

| Supply Chain | Difficulty enforcing consistency with suppliers. | Standardized, digital data improves clarity and efficiency across the supply chain. |

The Bottom Line: By providing free, standards-compliant examples, Action Engineering is lowering the barrier to entry for MBD. This accelerates the move toward a fully digital workflow—or “digital thread”—which promises reduced manufacturing costs, fewer errors, and faster product development for the entire industry.

Industry professionals have until January 20, 2026 to access the models and provide feedback, ensuring the final release is as practical and robust as possible.

The primary source was EIN Presswire.